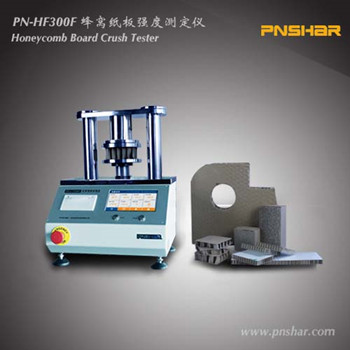

Honeycomb Board Crush Tester

Categories:Other Lab Tester

Name:Honeycomb Board Crush Tester

Model:PN-HF300

PN-HF300F honeycomb board crush tester is a new type high-precision intelligent tester researched and developed by our company in accordance with relevant national standards

Download:

Video:Click Play

Introduction

PN-HF300F honeycomb board crush tester is a new type high-precision intelligent tester researched and developed by our company in accordance with relevant national standards. It is mainly applicable to the flat compression strength (FCT) of honeycomb fiberboard with a thickness of 5.0mm ~ 40.0mm. It is a tester with very high cost performance in China. Flat compression strength: The maximum pressure per unit area, expressed in kilopascals (kPa).

The compressive strength mainly affects the cushioning performance of the honeycomb fiberboard. The higher the compressive strength, the better the cushioning performance of the honeycomb carton made. Honeycomb fiberboard has a much higher compressive strength than corrugated paperboard. In addition to making honeycomb box, honeycomb fiberboard is also a good cushioning material to protect products.

This tester is an electromechanical integration structure, and adopts modern mechanical design concept and microcomputer processing technology for careful and reasonable design. The tester adopts the fixing upper platen, with high measurement accuracy. PN-HF300F honeycomb fiberboard strength tester has functions of parameter testing, conversion, adjustment, memory, pressure curve real-time display, data printing and other functions included in the standard. It has powerful data processing functions, can directly get the statistical results of various data, and can automatically reset, easy to operate, easy to adjust, and stable performance.

The compressive strength mainly affects the cushioning performance of the honeycomb fiberboard. The higher the compressive strength, the better the cushioning performance of the honeycomb carton made. Honeycomb fiberboard has a much higher compressive strength than corrugated paperboard. In addition to making honeycomb box, honeycomb fiberboard is also a good cushioning material to protect products.

This tester is an electromechanical integration structure, and adopts modern mechanical design concept and microcomputer processing technology for careful and reasonable design. The tester adopts the fixing upper platen, with high measurement accuracy. PN-HF300F honeycomb fiberboard strength tester has functions of parameter testing, conversion, adjustment, memory, pressure curve real-time display, data printing and other functions included in the standard. It has powerful data processing functions, can directly get the statistical results of various data, and can automatically reset, easy to operate, easy to adjust, and stable performance.

Technical parameter

Power supply: AC100~224V±10% 2A 50/60Hz

Error of indication: ±1%

Resolution: 0.1N

Measuring range: (5 ~ 5000)N

Sampling size: Length or diameter of 60mm or at least 4 complete lattice.

Parallelism: ≤ 0.05 mm

Max distance: (2 ~ 70)mm

Test speed: 1 mm/min

Return speed: (5 ~ 30) mm/min

Display: 7” Touch screen.

Printer: Thermal printing

Data output: RS232(Standard) / USB(Optional)

Work environment:Temp.(20 ± 10 )°C relative humidity < 85%

Dimension: (375 × 345 × 505 ) mm(L×W×H)

Net Weight: About 38.6 kg

Error of indication: ±1%

Resolution: 0.1N

Measuring range: (5 ~ 5000)N

Sampling size: Length or diameter of 60mm or at least 4 complete lattice.

Parallelism: ≤ 0.05 mm

Max distance: (2 ~ 70)mm

Test speed: 1 mm/min

Return speed: (5 ~ 30) mm/min

Display: 7” Touch screen.

Printer: Thermal printing

Data output: RS232(Standard) / USB(Optional)

Work environment:Temp.(20 ± 10 )°C relative humidity < 85%

Dimension: (375 × 345 × 505 ) mm(L×W×H)

Net Weight: About 38.6 kg

Product features

Adopt new module circuit design with WIFI Internet of Things function. After networking test results can be saved to the cloud server and query and generate reports through the dedicated QMS quality management system;

After the test return at high speed to improve test efficiency;

Imported stepper motor servo control high positioning accuracy;

Over-range alarm function to protect precision sensors;

Using high-speed ARM processor high degree of automation fast data acquisition fully automatic measurement intelligent judgment function safe and reliable;

Adopt 24-bit high-precision AD converter (resolution up to 1 / 10000000) and high-precision load cell to ensure the fast and accurate data acquisition of instrument force values;

Can display pressure and deformation curve graph real-time display information such as anti-stress deformation;

Adopt modular integrated thermal printer with fast printing speed and convenient paper changing;

Can be connected to computer software with real-time display pressure curve function and data analysis management saving printing and other functions..

After the test return at high speed to improve test efficiency;

Imported stepper motor servo control high positioning accuracy;

Over-range alarm function to protect precision sensors;

Using high-speed ARM processor high degree of automation fast data acquisition fully automatic measurement intelligent judgment function safe and reliable;

Adopt 24-bit high-precision AD converter (resolution up to 1 / 10000000) and high-precision load cell to ensure the fast and accurate data acquisition of instrument force values;

Can display pressure and deformation curve graph real-time display information such as anti-stress deformation;

Adopt modular integrated thermal printer with fast printing speed and convenient paper changing;

Can be connected to computer software with real-time display pressure curve function and data analysis management saving printing and other functions..

National standard

GB/T 1453、BB/T 0016

Relevant information

NO