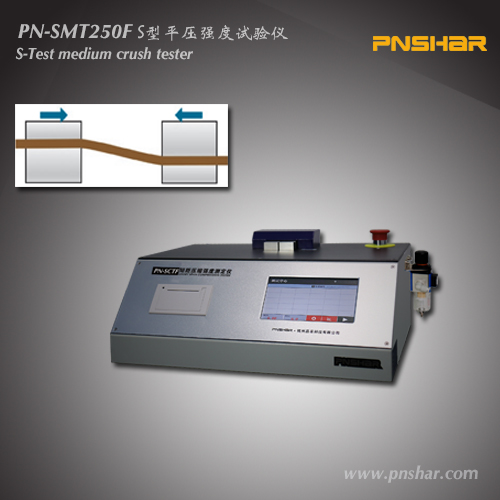

PN-SMT250F S-Test Medium Crush Tester

Categories:Other Lab Tester

Name:PN-SMT250F S-Test Medium Crush Tester

Model:PN-SMT250F

1. Power supply: (100 ~ 240)VAC 2A 50/60 Hz; 2. Indication error: 1%; 3. Indication repeatability: 1%; 4. Resolution: 0.01N; 5. Measuring range: 250N; 6. Air source pressure: (0.6~0.8)MPa; 7. Clamp spacing: 4mm; 8. Clamp offset: 1mm; 9. Sample widt

Introduction

Technical parameter

1. Power supply: (100~240)VAC 2A 50/60 Hz;

2. Indication error: ±1%;

3. Indication repeatability: ≤1%;

4. Resolution: 0.01N;

5. Measuring range: ≤250N;

6. Air source pressure: (0.6~0.8)MPa;

7. Clamp spacing: 4mm;

8. Clamp offset: 1mm;

9. Sample width: 15mm;

10. Test speed: (3±1) mm/min;

11. Human-machine interface: 7" color touch screen;

12. Print output: Modular integrated thermal printer

13. Communication output: WIFI, RS232 (standard)/USB (optional);

14. Working environment: Indoor temperature (20±10)℃, relative humidity <85%.

15. Overall dimensions: (466×410×360)mm, (length×width×height);

16. Net weight: about 42kg.

Product features

2. With an emergency stop button, it has alarm safety protection functions such as over-range;

3. The clamping force of the sample can be adjusted, and the preset parameters can realize one-key test;

4. Optimize the test program, realize rapid test and improve test efficiency;

5. It has the display function of curve and column chart, which is convenient for checking the test results;

6. The unit can be switched: N, kgf, lbf;

National standard

Relevant information

PN-SMT250F S-Test Medium Crush Tester is a new method for evaluating the flat crush performance of corrugated base paper. Compared with CMT testing, it has the following advantages:

1. Save test time and improve test efficiency. For example, CMT30 takes 30 minutes or more, while S-Test Medium Crush Tester only need several seconds;

2. There are few influencing factors. The test results of CTM will be affected by the performance of the pressure-sensitive tape, and the temperature and pressure of the corrugating equipment will also affect the CMT results;

3. The CMT test process is prone to ripples, which also affects the test results

Working principle: Clamp a 15mm wide sample between two clamps 4mm apart and 1mm offset from the center. Compress the sample into an "S" shape at a certain speed. Measure the maximum force value of this process and calculate the compressive strength.